Heat pump adoption has been ramping up in order to replace greenhouse gas-emitting space and water heaters in homes with safe, clean, all-electric alternatives. In San Mateo County, multiple jurisdictions have passed requirements that require new homes to all-electric technology; and over 100 customers apply for Peninsula Clean Energy’s heat pump installation rebates every month.

Retrofitting a building to use all-electric systems is not always as easy as designing all-electric for new construction. Layout issues, electrical capacity, and lack of space in California’s smaller housing stock can pose challenges. We will need access to a wider variety of heat pump configurations to help with a cost-effective energy transition.

As an architectural engineer who has designed low-carbon buildings across the globe, I can say with certainty that we had limited options in the U.S. when it comes to styles of electric heating systems. But, that is changing. Peninsula Clean Energy is working to pilot innovative systems that can make the energy transition more accessible and affordable for our constituents, customers, and neighbors.

Harvest Thermal Pilot

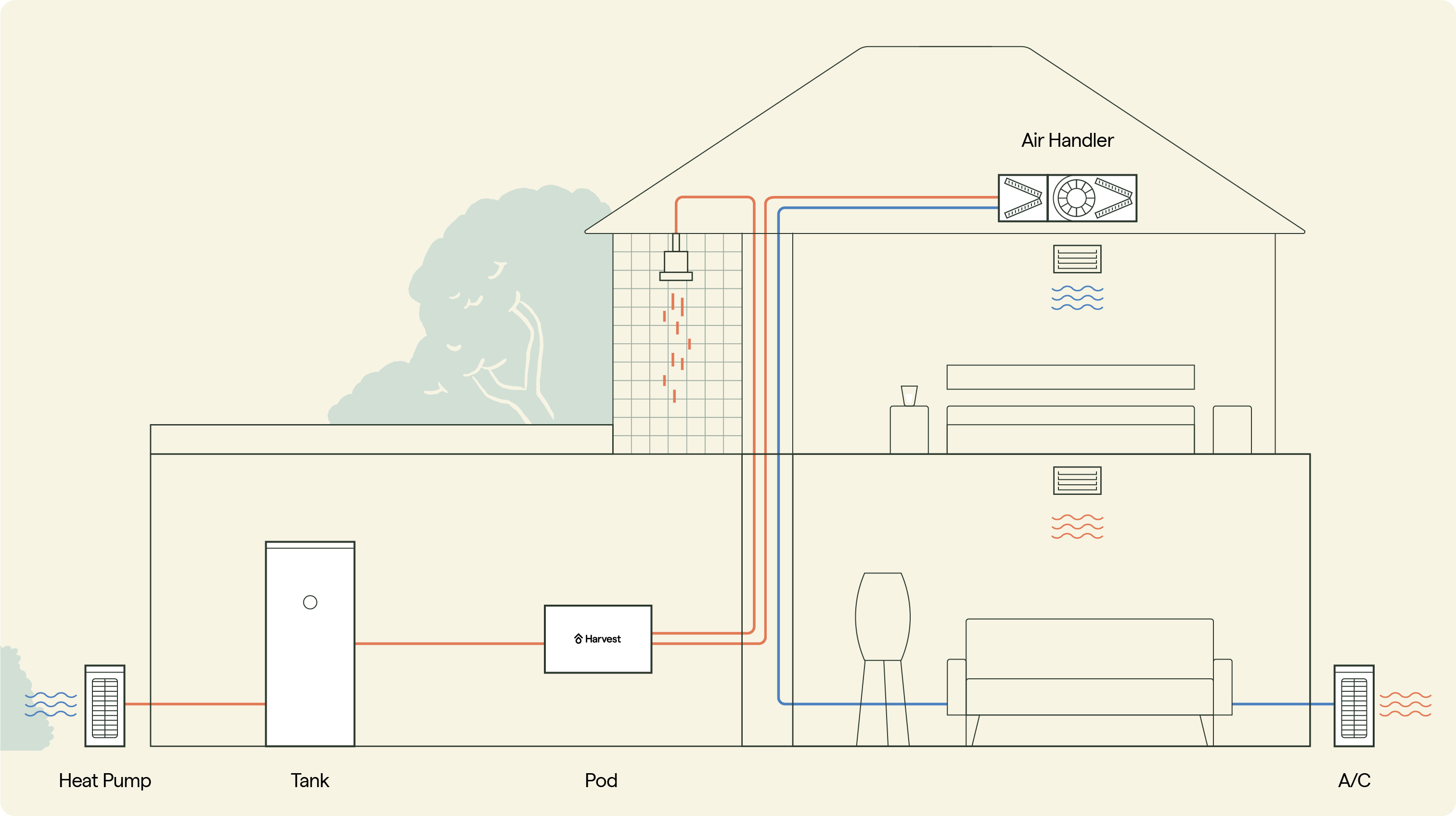

Peninsula Clean Energy recently worked with local start-up, Harvest Thermal, to pilot their new heat pump technology, which features a shared compressor with the following benefits:

- 2-in-1 System – The single compressor provides both heating and water heating, reducing the number of compressors needed to electrify the home

- Heating load flexibility – due to the thermal energy storage tank, heating loads can be moved away from the evening peak to save money and help enable the direction toward 24/7 carbon free electricity

- No indoor compressor – by moving the heat pump water heater compressor outdoors, issues with noise or venting are eliminated

- CO2 refrigerant – the system uses an ultra-low global warming potential (GWP) refrigerant, ensuring refrigerant leakages do not result in the greenhouse gas savings we are trying to avoid with electrification

Peninsula Clean Energy installed the Harvest Thermal system at four single-family homes in which TRC, a global consulting engineering and construction management firm, conducted independent measurement and verification (M&V) testing.

About the installations

The four homes in the pilot study are in: Daly City, Redwood City, South San Francisco, and Menlo Park. They were built between 1947 and 1980, and range from 1,060 to 1,950 square feet. Each home has two to four occupants and does not have air conditioning.

Installed costs were similar to installing separate equipment

By using a single compressor to serve both water heating and space heating needs, there is a potential opportunity for cost reductions. However, the system requires a more complex installation. Total installed costs averaged $28,600 per home, and $22,500 after incentives. This is a similar cost to installing a separate heat pump water heater and split system, ducted space heater in a single-family home in San Mateo County.

Energy cost savings

The energy cost savings of the Harvest Thermal System are due to:

- High-efficiency, all-electric heat pump system instead of methane gas

- Ability to use the storage tank to move loads from times of high, peak-load electricity rates to lower, off-peak electricity rates.

- Making sure that the customer is on an electrification-friendly rate, such as EV2A in San Mateo County

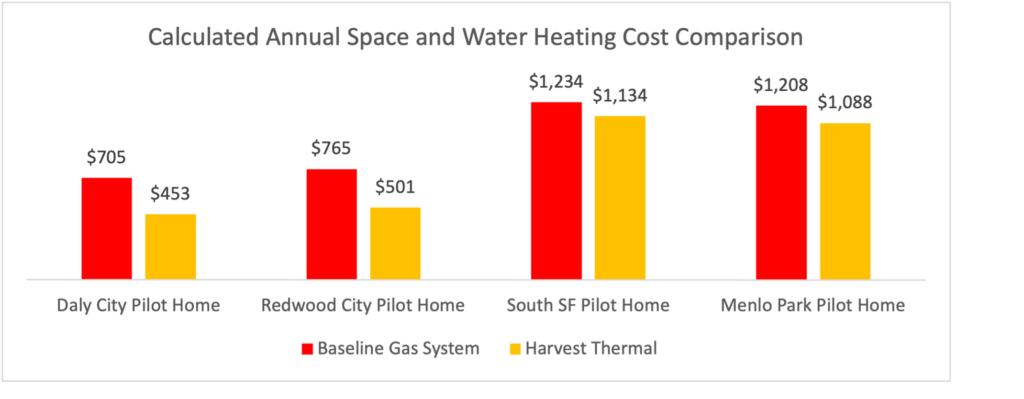

There was an average energy cost savings of 22% versus the gas baseline if the EV2A rate was used, and up to 36% energy cost savings. The study also found that switching to an electrification-friendly rate is key to ensuring energy costs savings. The figure below outlines the annual operating cost comparison at each pilot home.

Load flexibility benefits

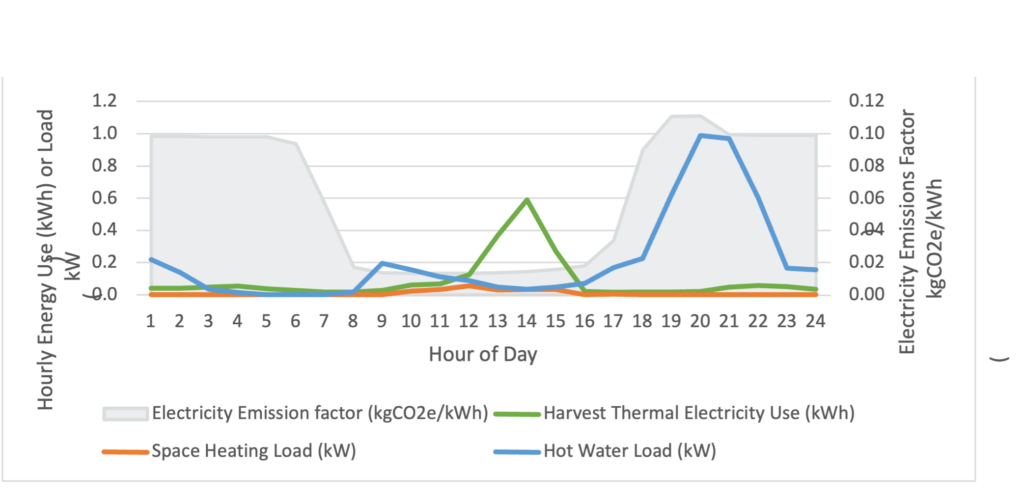

Grid-integrated buildings are becoming more important as we move to 100% renewable electricity that depends on available wind, solar, geothermal, and hydroelectric resources. The ability to flex loads in our homes helps reduce the amount of battery storage needed on the grid.

For space heating equipment, the ability to shift electricity associated with heating loads to the daytime, when solar electricity is available, is especially important. Traditional heat pump space heating systems do not offer load flexibility. With the shared compressor, the Harvest Thermal system shifted 3.6 kWh of electricity away from peak hours on average per day, an average of 860 kWh per year. These load shifts result in energy cost savings for the customer, help lower infrastructure costs for the state, and can help enable higher adoption of renewable electricity.

Opportunities for improvement

The Harvest Thermal system has some drawbacks versus traditional systems. The system piloted did not provide air conditioning. While most homes in our region operate without air conditioning, rising temperatures and increased smoke due to wildfires are leading to more interest in this feature.

Also, since it is a new system, contractors may not be familiar with it. Contractor awareness and education will be important for market penetration of new technologies like this.

Customer satisfaction

In general, customers liked the Harvest Thermal system better than their previous gas appliances, both for space heating and water heating, and were satisfied with the installation experience.

Read the pilot project final report.

Special discount for Peninsula Clean Energy customers

Harvest Thermal is offering an equipment discount of $500 to Peninsula Clean Energy customers.

By:

Blake Herrschaft

Building Electrification Program Manager

Peninsula Clean Energy